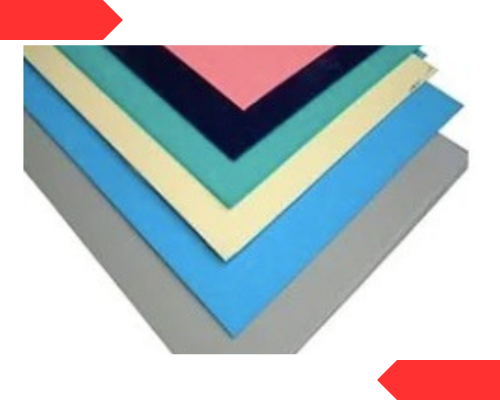

ESD Plastic Sheets

ESD (Electrostatic Discharge) extruded sheets are specialized materials designed to control and dissipate static electricity. They find applications in various industries where protection against electrostatic discharge is crucial. In this section, we will explore the applications, requirements, surface resistivity, and advantages of ESD extruded sheets.

Applications:

Electronics Industry:

ESD extruded sheets are extensively used in the electronics industry. They are employed for the manufacturing of sensitive electronic components, circuit boards, trays, and packaging materials. ESD sheets prevent the build-up and discharge of static electricity, ensuring the protection of electronic devices from potential damage caused by electrostatic discharge.

Automotive and Aerospace Industries:

ESD extruded sheets have applications in the automotive and aerospace sectors. They are used for manufacturing components and fixtures that come into contact with electronic systems or sensitive equipment. ESD sheets help safeguard critical electronic systems, ensuring their reliable operation and preventing potential damage caused by electrostatic discharge.

Manufacturing and Assembly:

ESD extruded sheets find applications in manufacturing and assembly environments where electrostatic discharge can harm sensitive components or products. They are used for workbench surfaces, shelves, trolleys, and containers to provide a static-safe working environment. ESD sheets help protect sensitive materials from damage during handling, transportation, and assembly processes.

Cleanroom Environments:

ESD extruded sheets are utilized in cleanroom environments, such as semiconductor manufacturing facilities, pharmaceutical labs, and biotechnology research centers. They are used for flooring, walls, and work surfaces to prevent the build-up of static electricity and protect sensitive equipment and products from electrostatic discharge.

Requirements:

Surface Resistivity:

ESD extruded sheets have specific surface resistivity requirements. The surface resistivity refers to the ability of the material to resist or conduct the flow of electric charges. In the case of ESD sheets, the resistivity is carefully controlled to provide the desired level of static dissipation. The surface resistivity of ESD sheets typically falls within a specific range, such as 10^4 to 10^11 ohms/square, depending on the application requirements.

Consistent Conductivity:

ESD extruded sheets should exhibit consistent conductivity throughout the material to ensure effective static dissipation. Uniform conductivity allows for reliable and predictable performance in controlling and dissipating static electricity. It ensures that the entire surface of the sheet provides consistent protection against electrostatic discharge.

Surface Resistivity:

ESD extruded sheets have a controlled surface resistivity that falls within a specific range. The surface resistivity is typically measured in ohms per square (Ω/sq). The resistivity of ESD sheets is engineered to allow for controlled dissipation of static charges. The specific resistivity requirements may vary depending on the application and industry standards.

Advantages:

Electrostatic Discharge Protection:

The primary advantage of ESD extruded sheets is their ability to provide effective protection against electrostatic discharge. They prevent the build-up of static electricity and ensure controlled dissipation of charges, protecting sensitive electronic components, devices, and equipment from damage caused by electrostatic discharge.

Component and Product Protection:

ESD extruded sheets offer reliable protection for sensitive components and products. By preventing electrostatic discharge, they help maintain the integrity and functionality of electronic components, preventing malfunctions or failures due to static electricity. ESD sheets are essential in industries where electrostatic discharge can lead to costly damages or product defects.

Safety and Compliance:

ESD extruded sheets contribute to a safer working environment, particularly in industries where electrostatic discharge poses a safety risk. By dissipating static charges, they minimize the chances of sparks or ignition in potentially explosive or flammable environments. ESD sheets also ensure compliance with industry standards and regulations related to electrostatic discharge protection.