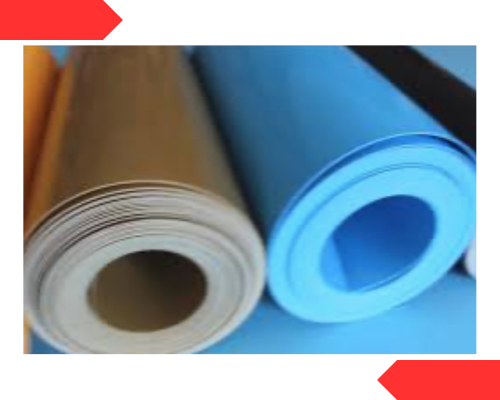

Polypropylene Sheets

Polypropylene (PP) extruded sheets are widely used in numerous industries due to their exceptional properties and versatility. PP is a thermoplastic polymer known for its high chemical resistance, durability, and low density. In this section, we will explore the applications and advantages of PP extruded sheets.

Applications:

Packaging Industry:

PP extruded sheets find extensive use in the packaging industry. They are employed for the production of various packaging materials such as food containers, blister packaging, clamshells, and protective packaging. PP sheets offer excellent chemical resistance, moisture resistance, and clarity, making them ideal for storing and showcasing a wide range of products. They can be easily thermoformed, allowing for the creation of customized packaging designs.

Automotive and Transportation:

PP extruded sheets are widely utilized in the automotive and transportation sector. They are used for interior components such as door panels, dashboard components, and seat backs. PP sheets offer high impact strength, dimensional stability, and resistance to UV radiation, ensuring their durability and longevity in automotive applications. They can be easily formed and fabricated to meet specific design requirements.

Building and Construction:

PP extruded sheets have various applications in the building and construction industry. They are used for roofing sheets, wall claddings, partitions, and insulation boards. PP sheets offer good dimensional stability, impact resistance, and resistance to chemicals and moisture, making them suitable for outdoor and construction applications. They can be easily cut, shaped, and joined to create durable and weather-resistant structures.

Electrical and Electronics:

PP extruded sheets find applications in the electrical and electronics industry. They are used for manufacturing battery housings, electrical enclosures, and insulating components. PP sheets offer good electrical insulation properties, flame retardancy, and resistance to chemicals, making them suitable for these applications. They can be easily machined, drilled, and fabricated to create precise components.

Agriculture:

In the agricultural sector, PP extruded sheets are used for various purposes. They are employed for greenhouse roofing, irrigation pipes, and agricultural containers. PP sheets offer excellent chemical resistance, UV resistance, and durability, making them ideal for harsh agricultural environments. They can withstand exposure to chemicals, sunlight, and extreme temperatures, ensuring the longevity of agricultural structures and equipment.

Advantages:

Chemical Resistance:

PP extruded sheets exhibit excellent chemical resistance, making them suitable for applications where exposure to acids, alkalis, and solvents is common. They are resistant to a wide range of chemicals, ensuring the integrity of the material and maintaining the safety of the products or components they are used in. This property allows for their use in packaging hazardous substances and corrosive materials.

Lightweight:

PP extruded sheets have a low density, making them lightweight compared to many other materials. This lightweight nature offers advantages such as reduced transportation costs, improved fuel efficiency in vehicles, and ease of handling during installation and fabrication. Additionally, the lightweight nature of PP sheets contributes to the overall weight reduction of finished products.

Durability:

PP extruded sheets offer excellent durability, ensuring their longevity in various applications. They are resistant to impact, abrasion, and weathering, making them suitable for both indoor and outdoor use. PP sheets retain their structural integrity even in challenging environments, reducing the need for frequent replacements and maintenance.

Cost-Effective:

PP extruded sheets offer cost advantages in terms of material cost and processing. PP is a relatively inexpensive polymer, making it a cost-effective choice for applications where high volumes of material are required. Additionally, the extrusion process used to produce PP sheets is efficient, allowing for high-speed production and reduced manufacturing costs.